The manufacturing industry has always been at the forefront of technological advancements. From the Industrial Revolution to the automation of processes, manufacturers are constantly looking for ways to improve efficiency and quality.

What is a Water Jet Cutting Machine?

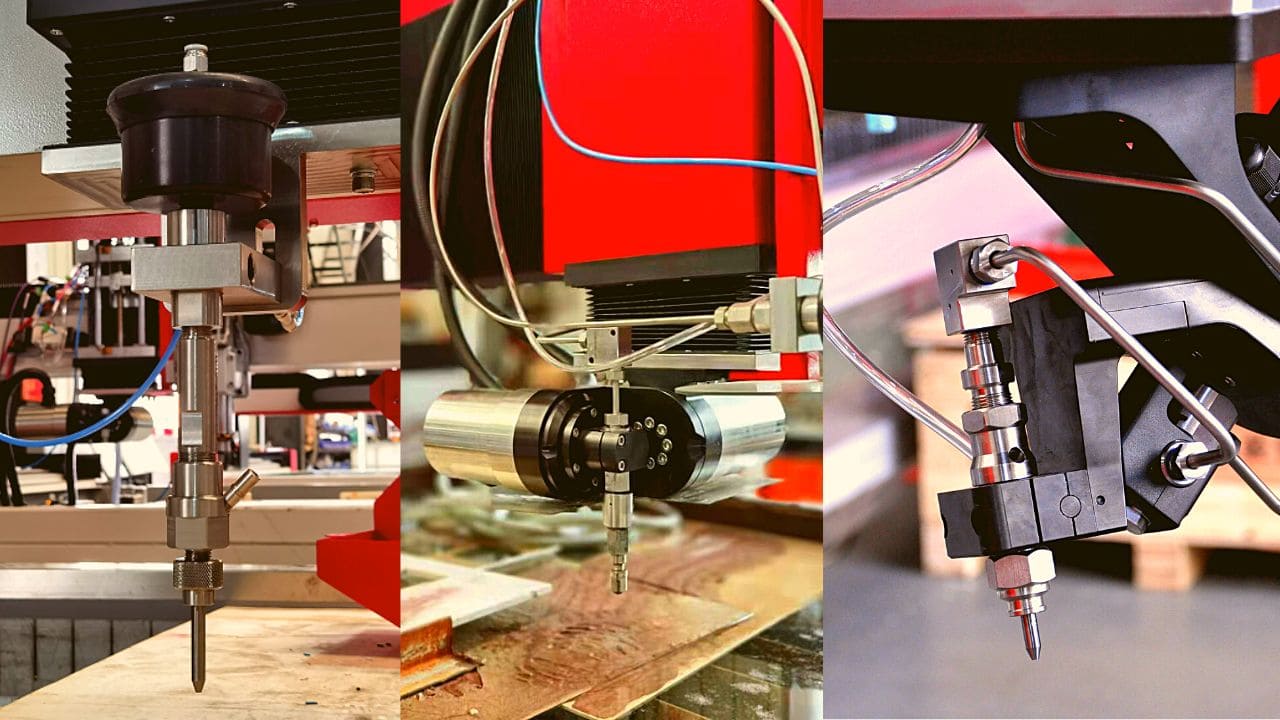

A water jet cutting machine is a tool that uses a high-pressure stream of water to cut through materials. This technology has been around since the 1970s but has gained popularity and widespread use in recent years due to its numerous advantages over traditional cutting methods. OMNI CNC systems are designed to be highly reliable and precise, providing users with consistently high-quality machining results. Its hardware and software are designed to be user-friendly and easy to use, allowing for fast and efficient setup and operation.

Applications of Water Jet Cutting

The versatility and precision of water jet cutting make it suitable for a wide range of applications in various industries: automotive, aerospace, manufacturing, architecture, and even food processing. Water jet cutting can easily cut through materials such as metal, stone, glass, rubber, and even food products. Its ability to cut intricate shapes and designs with precision makes it ideal for producing parts and components in industries such as automotive and aerospace.

The Future of Water Jet Cutting

The water jet-cutting industry is witnessing continuous advancements and innovations. Manufacturers are developing more powerful pumps and cutting heads to improve cutting speed and efficiency. Additionally, the integration of robotics and automation is enabling manufacturers to further enhance productivity and reduce labor costs.

Conclusion

Water jet-cutting machines have revolutionized the manufacturing industry with their versatility, precision, speed, and cost-effectiveness. They have found applications in various industries, from aerospace to food, and continue to evolve with advancements in technology. As manufacturers strive for higher efficiency and quality, water jet-cutting machines will undoubtedly play a significant role in shaping the future of manufacturing.