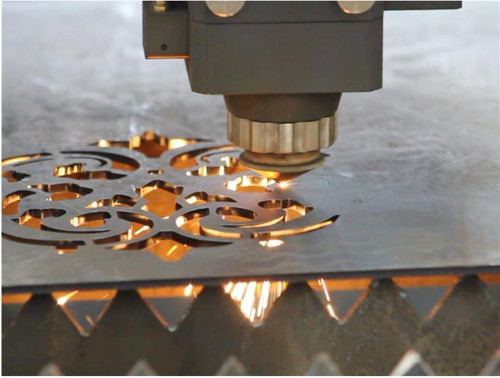

Laser cutting is a form of modern manufacturing technology used to cut a variety of materials. It is a highly precise method of cutting shapes and holes in materials and has become an integral part of the manufacturing process.

Laser cutting service is used by a wide range of industries, including automotive, aerospace, medical, and construction. If you want to know more about laser cutting service then, you may check https://www.lasermicromachining.com/.

Image Source: Google

The laser cutting process works by focusing a high-energy beam of light on a material, which melts, burns, or vaporizes it. The laser beam is directed by a computerized system that translates the design into an automated cutting path.

This cutting path can be programmed to create intricate and complex shapes with great precision. The laser cutting process can be used to cut materials such as metals, plastics, and wood.

The primary advantage of laser cutting is its precision. Laser beams can be focused to a very small area, allowing for complex shapes to be accurately cut with minimal wastage. This makes it ideal for creating intricate designs and prototypes.

Another advantage of laser cutting is its speed. Laser cutters can be programmed to cut multiple layers of material quickly and with minimal waste. This makes it an efficient way to mass-produce parts and components.

Laser cutting is also highly economical. It is a relatively low-cost process, and its speed and precision allow for mass production of parts and components with minimal wastage. This makes it an ideal solution for many manufacturing applications.